Products

These products stand out among all that we offer:

Oil conditioning

Electrical switchboards

Automation

Control desk

Thrusters control

Energy efficiency

Electrical switchboards

Main switchboard

Distribution switchboards

Motor control center

Panels

Oil conditioning

Transdiag

Transcond

Automation

Design, development, assembly and commissioning of our automation system to suit the client.

IM-AUT 4.0 is the last version of the automation system of Itxas Marine to carry out alarms, control, supervision, data logging and remote maintenance tasks in modern vessels.

The heart of the system is composed by two redundant PLC-s from Mitsubishi iQ-R series. Both PLC-s are managing the system control in real time, one working as the master PLC and the second one as st-by. In case of malfunction, the standby PLC takes the control.

Beijer Scada applications enable operators to monitor and operate the IAS through the user stations.

Some functions of the system are:

Alarm system

Power management system

Temperature control & monitoring system

Display of equipment-systems

System control

Communications diagram

Count hours

Control desk

Ergonomic design, metal fabrication and electrical engineering development, equipment integration (nautical and radio navigation instruments, control and monitoring,…). Assembly and final connection onboard.

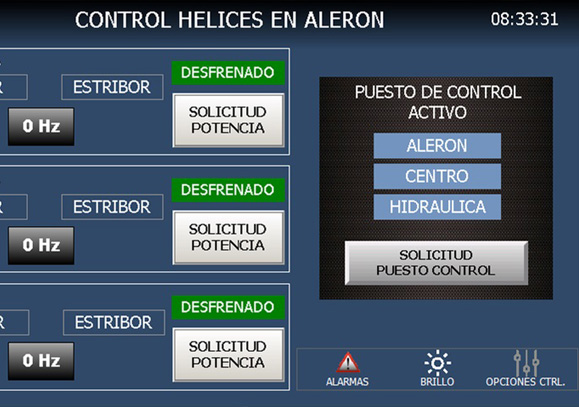

Thrusters control

IITXASMARINE has the transversal thrusters control system IM-TTC2.0

This system has been designed to provide an intuitive operability to the operator including alternative operating modes in the face of a failure. The IM-TTC2.0 is made up of high-performance Mitsubishi hardware which provides great reliability, backed by its wide experience in the naval market.